Welding Holding Fixtures Manufacturer

We are Manufacturer, Supplier (and Fixtures Services Provider, Fixtures Solutions Provider) of Welding Holding Fixtures, Holding Fixtures, Holding Fixture Resting. Our setup is situated at Pune, Maharashtra, India. Majorly we target customers from ALL OVER MAHARASHTRA.

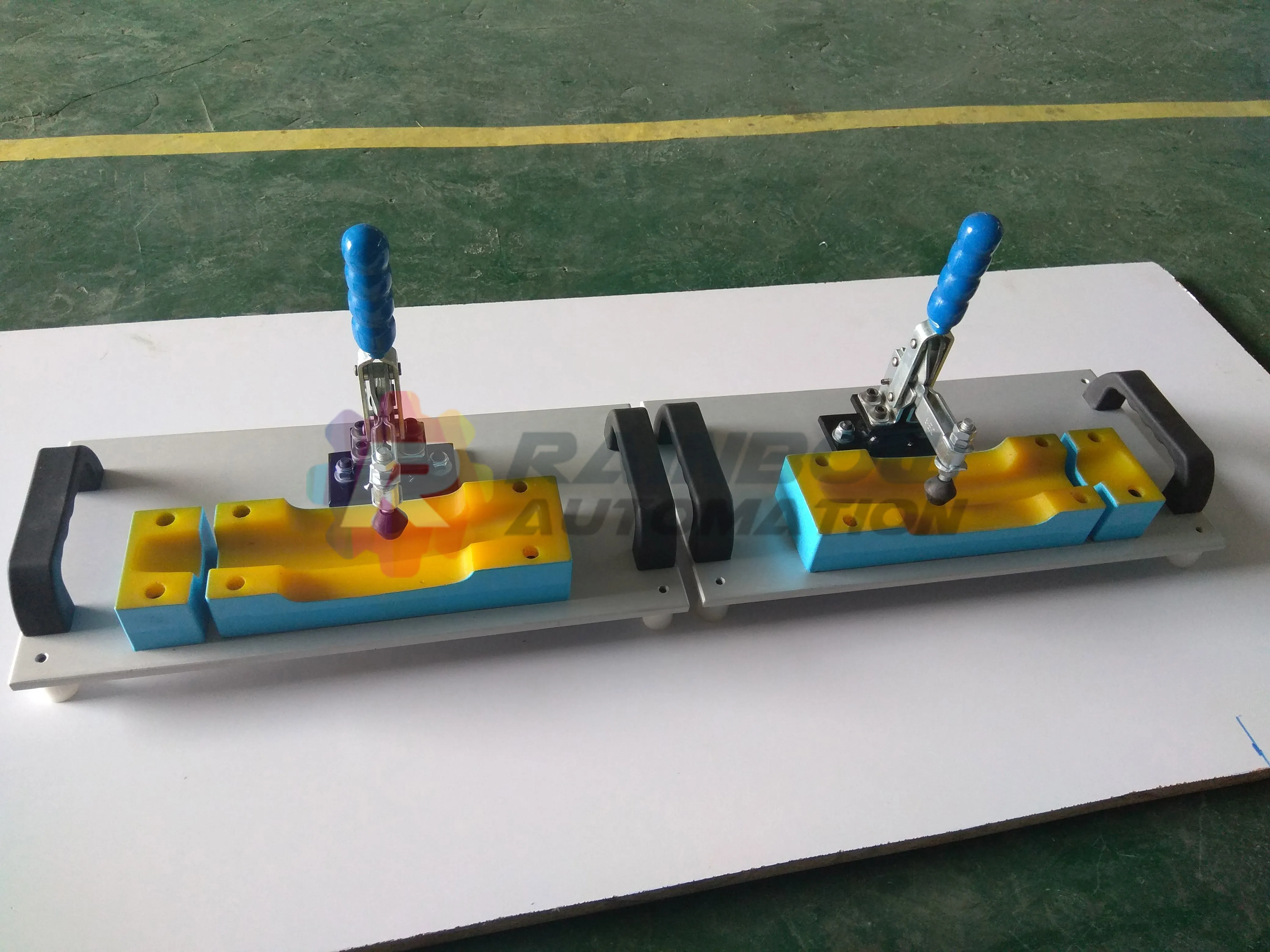

Holding fixtures are devices used to secure and position workpieces during machining or assembly processes, ensuring accurate and consistent results. They contain clamps, supports, or other mechanisms to hold the workpiece securely in place.

Holding Fixtures and Welding Holding Fixtures are essential tools used to securely position and hold workpieces during machining or welding operations. These fixtures are designed to prevent movement or misalignment, ensuring that the welding or machining process is precise and accurate. Built from high-quality materials such as SS (Stainless Steel) and MS (Mild Steel), these fixtures are durable and provide reliable support during heavy-duty industrial processes. Holding Fixtures are customizable to accommodate various shapes and sizes of workpieces, making them highly versatile for different industrial applications. Welding Holding Fixtures specifically aid in stabilizing components during welding to ensure a strong and accurate weld.

Salient Features:

- High precision and accuracy in positioning

- Made from SS (Stainless Steel) and MS (Mild Steel) for durability

- Customizable to fit various workpiece shapes and sizes

- Suitable for heavy-duty industrial operations

- Improved welding consistency and quality

Applications:

- Welding processes in automotive manufacturing

- Machining operations in industrial manufacturing

- Heavy machinery fabrication

- Aerospace component assembly