Ultrasonic Welding Fixtures Manufacturer

We are Manufacturer, Supplier, Exporter (and Fixtures Services Provider, Fixtures Solutions Provider) of Ultrasonic Welding Fixtures, Ultrasonic SS (Stainless Steel) / MS (Mild Steel) / Thermoplastics Welding Fixtures. Our setup is situated at Pune, Maharashtra, India. Majorly we target customers from ALL OVER MAHARASHTRA.

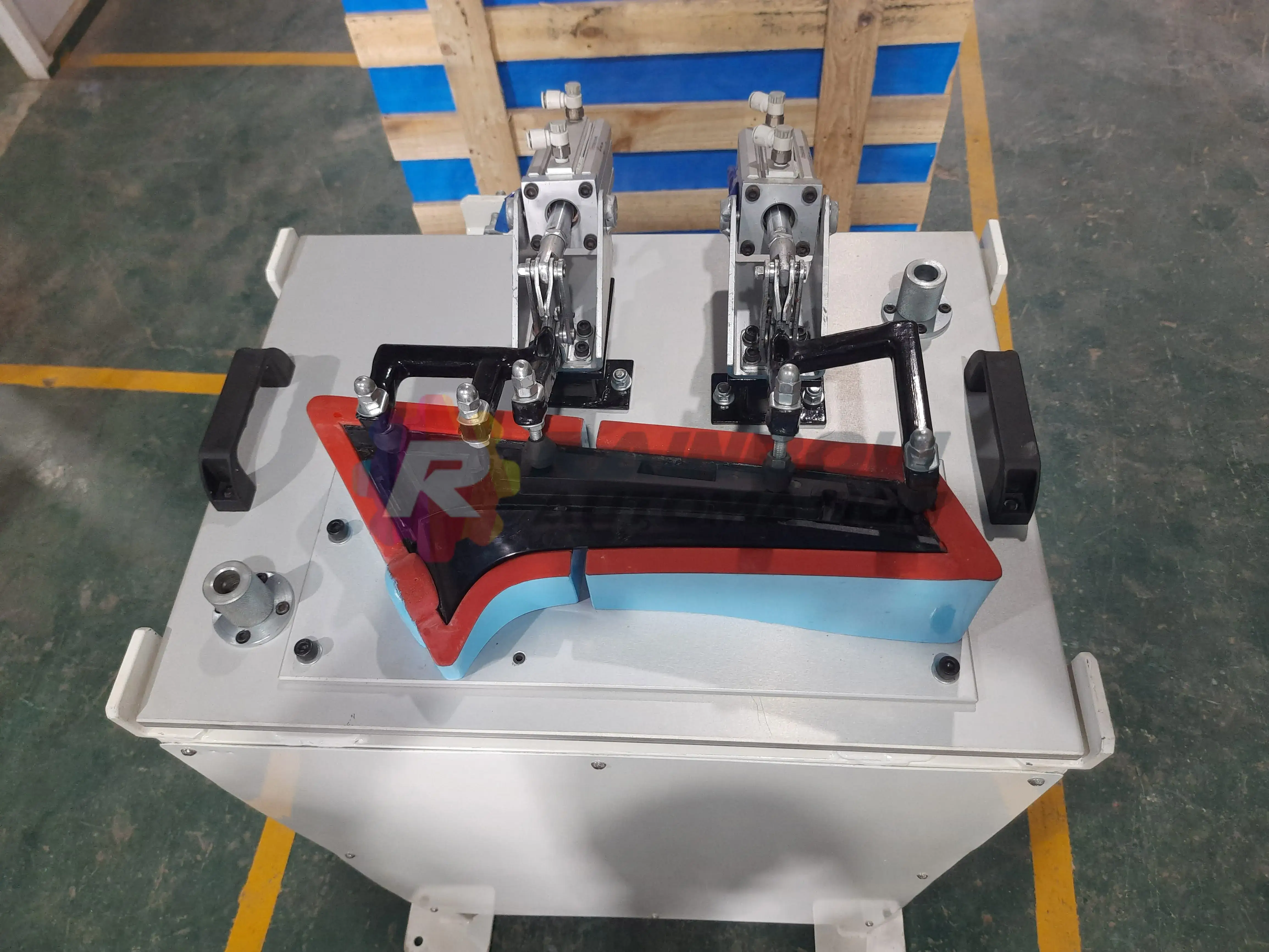

Ultrasonic Welding fixtures are devices used to hold and support parts during welding to ensure accurate and repeatable positioning. They contain clamps, supports, and guides to secure the components in the desired configuration, allowing for precise welding operations.

Ultrasonic Welding Fixtures are designed to enhance the efficiency and precision of ultrasonic welding processes, primarily used in industries such as automotive, electronics, and plastic manufacturing. These fixtures hold the workpieces securely in place while ultrasonic vibrations are applied to join the materials together. With ultrasonic technology, the fixtures ensure quick and precise welding without the need for additional heat or adhesives. The versatility of Ultrasonic Welding Fixtures allows them to handle different materials like SS (Stainless Steel), MS (Mild Steel), and thermoplastics, ensuring a strong and durable bond. These fixtures are customizable, offering solutions to meet the unique needs of each production line, contributing to higher productivity and cost efficiency.

Salient Features:

- Customizable designs to fit various welding applications

- Enhanced accuracy in welding processes

- Suitable for SS (Stainless Steel), MS (Mild Steel), and thermoplastics

- Robust construction for durability in industrial environments

- Quick changeover capabilities to reduce downtime

Applications:

- Automotive component manufacturing

- Electronics assembly

- Plastic fabrication

- Medical device production